The Most Unique Bridge In Pennsylvania Comes With A Fascinating Past

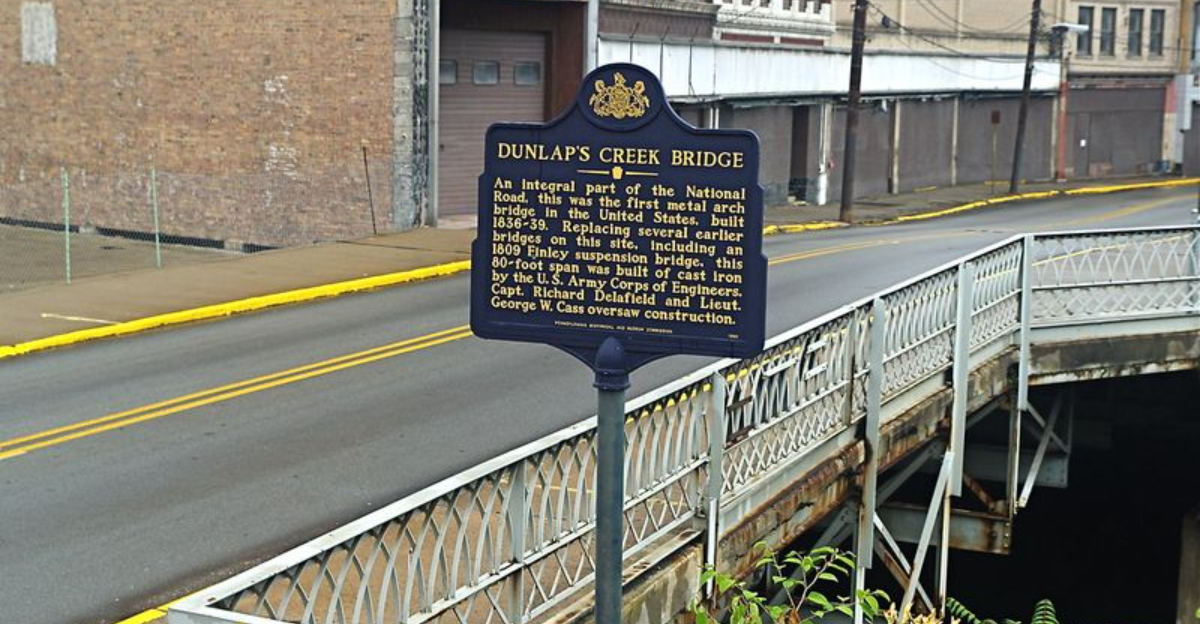

Pennsylvania holds many engineering marvels, but none quite like the Dunlap’s Creek Bridge in Brownsville.

This remarkable structure changed American bridge building forever when it opened in 1839. What makes this bridge so special isn’t just its age, but the groundbreaking materials and methods used to create it.

Get ready to discover why this humble bridge earned its place in history books.

1. America’s First Cast-Iron Arch Bridge

Back in the 1830s, most bridges were built from wood or stone. Engineers were getting tired of replacing wooden bridges that rotted or burned down every few years.

Cast iron offered a revolutionary solution that nobody had tried before in America. This new material promised strength and durability that traditional materials couldn’t match.

Dunlap’s Creek Bridge became the guinea pig for this bold experiment, marking a pivotal moment in construction history.

2. Three Years Of Careful Construction

Construction kicked off in 1836 with workers who had never built anything like this before. Nobody really knew if cast iron would hold up under the weight of wagons and horses.

Engineers took their sweet time, testing every piece and joint along the way. The project stretched over three years as builders learned new techniques on the job.

When the bridge finally opened in 1839, it represented countless hours of trial and error by determined craftsmen.

3. Designed By A Military Engineer

Richard Delafield wasn’t your average bridge designer. This U.S. Army Corps of Engineers officer brought military precision to civilian construction projects.

His engineering background gave him the confidence to experiment with untested materials and methods. Delafield studied European ironwork techniques and adapted them for American conditions.

The bridge reflects his methodical approach, combining innovative thinking with practical military engineering principles that ensured long-term success.

4. Part Of The Historic National Road

The National Road was America’s first major highway, stretching from Maryland to Illinois. Think of it as the Interstate 70 of the 1800s, connecting eastern cities with western frontier towns.

Dunlap’s Creek posed a serious obstacle for travelers and freight wagons crossing Pennsylvania. A reliable bridge here meant safer, faster travel for thousands of people.

The bridge became a crucial link in this transportation network that helped build our nation.

5. Still Carrying Traffic Today

Nearly 200 years later, cars still rumble across this old bridge on Market Street in Brownsville. Modern vehicles weigh way more than the horse-drawn wagons it was designed for.

Regular maintenance and careful monitoring keep the bridge safe for daily use. Engineers regularly inspect every rivet and joint to catch problems early.

Few structures from the 1830s still serve their original purpose, making this bridge a true working antique.

6. National Historic Engineering Landmark Status

In 1978, engineering experts officially recognized what locals had known for decades. The American Society of Civil Engineers designated the bridge as a National Historic Civil Engineering Landmark.

This honor puts it in the same category as the Brooklyn Bridge and Golden Gate Bridge. The designation celebrates structures that changed how we build things.

Only the most groundbreaking engineering achievements earn this prestigious recognition from professional engineers nationwide.

7. Listed On National Register

The National Register of Historic Places includes buildings, bridges, and sites that shaped American history. Getting on this list requires proving your historical importance to experts.

Dunlap’s Creek Bridge earned its spot by revolutionizing bridge construction techniques across the country. The listing helps protect the structure from demolition or major changes.

Federal recognition ensures future generations can see and appreciate this engineering milestone that changed American infrastructure forever.

8. Eighty-Foot Main Arch Span

The bridge’s main arch stretches 80 feet across Dunlap’s Creek, supported by five tubular ribs made from elliptical cast iron segments. Each rib was carefully calculated to distribute weight evenly.

These hollow tubes made the bridge lighter than solid iron while maintaining incredible strength. The elliptical shape resists bending better than round or square tubes.

This engineering math might sound boring, but it’s what keeps the bridge standing after nearly two centuries of use.

9. Two Centuries Of Proven Durability

Cast iron bridges were an untested gamble when this one was built. Nobody knew if the material would last five years, let alone two hundred.

Regular restorations have kept the original structure intact while addressing normal wear and tear. The basic framework remains exactly as Richard Delafield designed it.

This bridge proved that cast iron construction could outlast traditional materials, encouraging engineers nationwide to try similar projects.